Most Popular Products

Governing Standards & Designs

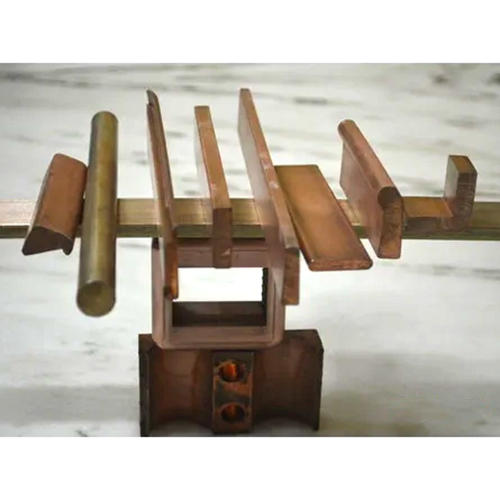

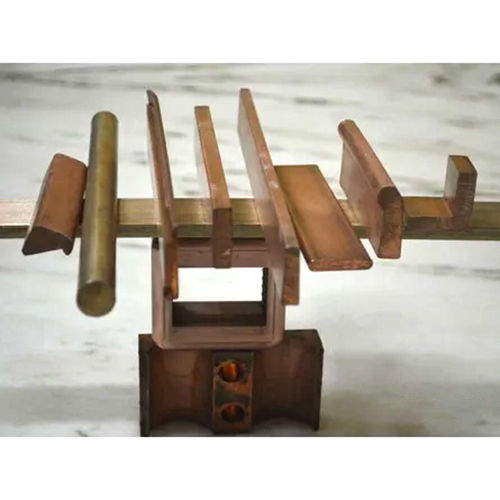

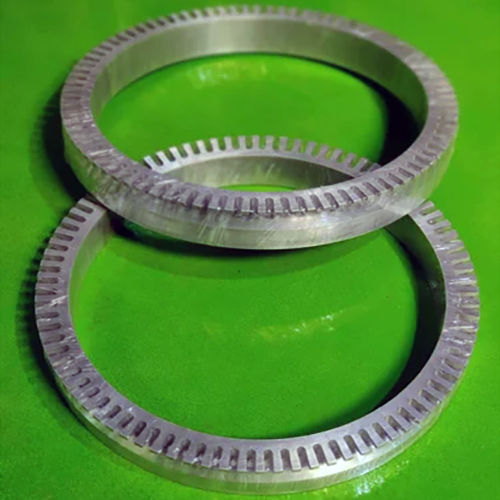

- Due to the variety of fields and customers we serve, we are familiar with operating in different industries & deliver products as per customer requirements. We manufacture almost all shape, size and section of Copper & Copper Based Alloys as per IS, DIN, and ASTM standards and customer's specifications.

- We have recruited an experienced team of professionals, who carry our business tasks as per our clients' requirements.

- Our team members are proficient enough to convert complex paper drawings and hand sketches into high-quality, precise and detailed products.

- We are projecting the accurate details related to shapes, sizes and dimensions of the mechanical parts via our professional designing solutions.

- At IMA, we study the preferences of the customers very carefully to develop product design in such a manner that it captures the components of the projects.

- Our keen attention to detail and our knowledge & experience of all kinds of materials like Aluminum, Copper, Brass and High Copper Alloys, etc. help in providing the quality which the customer expects.

- Our company offers quality custom manufacturing services as well.

Our Backbone, Our Team

Recruiting experienced and deserving candidates is the best move to make when it comes to attaining the success in the competitive domain. Considering the same, we have always followed a strict employee recruitment process. We not just hire the best candidates but also providing them the required training as per the processes and policies of our company. Like the roots of a tree, our employees help us in enjoying the fruits of success by remaining on their toes and fulfilling the demands of our customers without any hassle. The sheer hard work of our employees makes it easier for us to attain our set targets before deadline. Thus, we have been offering our clients only the best range of Copper Flats, Bare Aluminum and other metal products.

Client Contentment and Assured Quality

Ever since our foundation in 1963 when we began our business voyage, we have been raising our mark by offering quality-assured metal and alloy products to our clients. We have appointed a small group of quality analysts to ensure the same. They use technologically advanced quality testing tools to check final developed products. For this reason, our Bronze Rod, Aluminum Forgings and other metal products are highly demanded in the market. The parameters on which we quality check our alloys and metals are cited below:

- Chemical resistance

- Mechanical strength

- Physical properties

As a result, our clients consistently leave positive feedback with us after receiving orders from us.

Some of the testing facilities installed in our unit are listed below:

Some of the testing facilities installed in our unit are listed below:

- Fully Equipped In-house Complete Chemical Analysis Lab

- Spectro Chemical Analyzer (Bubker, Germany)

- Universal Testing Machine (Computerized, Krystal)

- Ultrasonic Flaw Detector (Ex 10 of EEC Make)

- Ultrasonic Flaw Detector (Digiscan DS-332)

- Ultrasonic Flaw Detector (Digiscan DS-334)

- Electrical Conductivity Test Equipment (Dr. Fosters Sigma, Germany)

- Electrical Conductivity Test Equipment (Fiescher, Germany)- 02 no.s

- Electrical Conductivity Test Equipment, Shiva- 3 No.s

- Resistance Micro Ohm Meter. Motwani-Pune (India)

- Hardness Testing Machine, Brinell (Krystal Elmec)

- Hardness Testing Machine, Rockwell (Krystal Elmec)

- Digital Portable Hardness Tester (Brinell)

- Hydraulic Pressure Testing 14000 Ibs/inch sq. (2No.s)

- Hydraulic Pressure Testing 500 Ibs/inch sq. (2No.s)

- Vernier Calipers, Micrometer, Degree Compass, Slotting Gauge, Radius Gauge, Filler Gauge, Surface Finish Gauge, etc. and other necessary measuring instruments.

|

INDIAN METALS & ALLOYS MFG CO.(P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese